LCZN

High-Speed CNC Coil Slitting & Rewinding Line

High-Speed CNC Coil Slitting & Rewinding Line

High-Speed CNC Coil Slitting & Rewinding Line

1. Product Overview

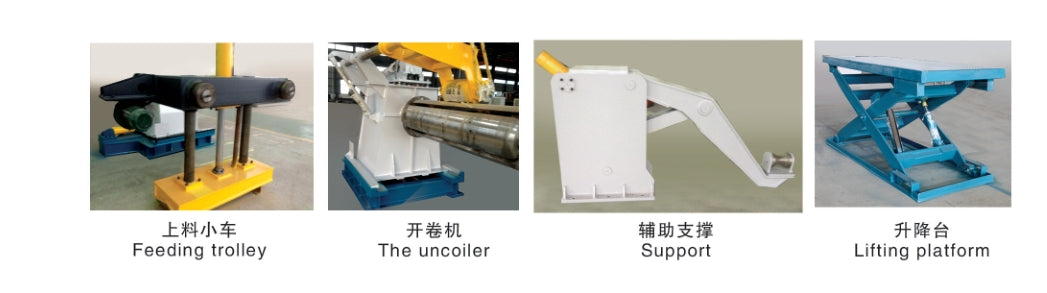

The High-Speed CNC Coil Slitting & Rewinding Line is an advanced metal processing solution designed for precise, efficient, and automated slitting of thin metal sheets. This production line is ideal for processing stainless steel, carbon steel, galvanized steel, aluminum, and other metal coils, making it an essential tool for industries requiring high-speed and high-precision coil slitting and rewinding.

This system integrates automatic uncoiling, leveling, precision slitting, tension control, and recoiling into a seamless operation, significantly improving production efficiency and reducing material waste.

2. Key Features

✅ CNC High-Precision Slitting – ±0.05mm accuracy ensures uniform slitting width.

✅ Automatic Coil Handling – Intelligent uncoiling, tension control, and rewinding system for stable operation.

✅ High-Speed Operation – Processing speed of up to 120m/min, boosting productivity.

✅ Customizable Blade Configuration – Flexible blade settings for different slitting width requirements.

✅ Advanced Tension Control – Ensures smooth and stable coil feeding without material distortion.

✅ User-Friendly PLC Control System – Touchscreen interface for easy operation and real-time monitoring.

✅ Heavy-Duty Structure – Designed for long-term durability and low maintenance requirements.

3. Competitive Advantages

🔹 Higher Efficiency – Faster production speed compared to traditional slitting machines, reducing processing time.

🔹 Superior Cutting Precision – Ensures high-quality slit edges, minimizing scrap rates.

🔹 Energy-Saving & Cost-Effective – Equipped with a smart energy-efficient drive system, reducing operational costs.

🔹 Versatile Application – Supports various metal coil thicknesses (0.2mm – 3.0mm) and widths, catering to multiple industries.

🔹 Reduced Labor Costs – Automated system minimizes manual intervention and enhances operational safety.

4. Applications

📌 Steel Processing Centers – Efficient slitting for customized steel processing.

📌 Automobile Manufacturing – Producing precision-cut steel sheets for body panels and components.

📌 Household Appliances – Slitting metal sheets for refrigerators, air conditioners, and washing machines.

📌 Building & Construction – Processing coils for roofing, wall panels, and structural steel.

📌 Metal Furniture Industry – Cutting raw materials for metal cabinets, shelves, and frames.

📌 Electronics & Electrical Equipment – Preparing metal strips for transformers and enclosures.

5. Technical Specifications

| Parameter | Specification |

|---|---|

| Material Thickness | 0.2mm – 3.0mm |

| Max Coil Width | 1600mm (Customizable) |

| Max Coil Weight | 25T (Customizable) |

| Slitting Speed | Up to 120m/min |

| Number of Slitting Strips | 3 – 30 strips |

| Slitting Accuracy | ±0.05mm |

| Tension Control | Fully automatic |

| Power Supply | 380V/50Hz (Customizable) |

| Control System | PLC with HMI Touchscreen |

6. Why Choose Our CNC Slitting Line?

✅ Over 10 Years of Expertise – Professional manufacturing and engineering team.

✅ Customizable Solutions – Tailor-made configurations to meet your production needs.

✅ Strict Quality Control – CE-certified components ensure reliability and long-term performance.

✅ Global Service & Support – Overseas installation and after-sales service available.

💡 Interested in enhancing your coil processing efficiency?

👉 Contact us today for a detailed quote and technical consultation!

Share

Contact us !