我的商店

Cut-to-Length Production Line

Cut-to-Length Production Line

Performance Features:

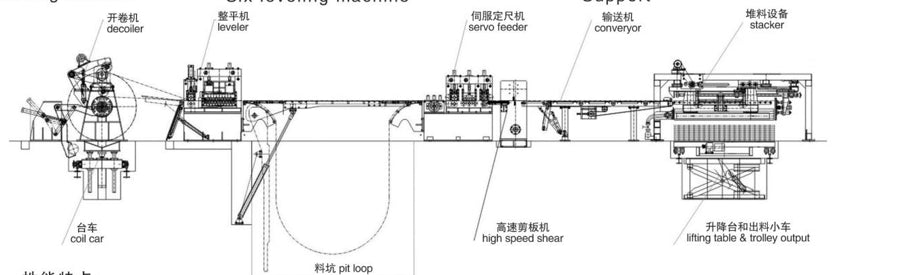

◆ This production line is a specialized system designed to flatten thin metal coils and shear them into plate blocks. It typically consists of a feeding trolley, uncoiler, plate support and tensioning device, main leveling unit, movable bridge, guiding and correction device, length measurement mechanism, lamination device, shearing machine, conveying worktable, pneumatic discharge rack, hydraulic lifting and stacking table, material transporting roller table, as well as a hydraulic system and an electrical control system. All components work in unison under PLC control, and key hydraulic, pneumatic, electrical control elements, and the length measurement system are selected from renowned brands.

◆ The equipment is primarily used for processing cold-rolled carbon steel coils, stainless steel coils, and non-ferrous metal coils. By employing a six-stage leveling machine, it is capable of flattening and length-shearing coils made from metals like aluminum, which require high surface quality.

◆ According to customer requirements, the leveling process can be executed using either a two-stage (primary and fine) leveling system; length feeding and shearing may utilize either conventional electromechanical coordination, digital variable frequency technology, or AC servo technology; and the shearing machine can be configured as a conventional mechanical type, a hydraulic type, a high-speed guillotine-type powered by hydraulic motors or pneumatic clutches, a mobile tracking cutter, or a rotary flying shear. Additionally, with compatible forming machines, the system’s functionality can be further extended.

Below is an English version of the table, with the corresponding technical parameters translated:

LCZN Series Main Technical Data

| Model | Sheet Thickness (mm) | Coil Width (mm) | Leveling Tolerance (mm) | Length Tolerance (mm) | Line Speed (m/min) | Coil Weight (t) |

|---|---|---|---|---|---|---|

| LCZN-2×650 | 0.3–2 | 150–650 | 1.2 | ±0.5 | 40 | 5 |

| LCZN-2×850 | 0.3–2 | 300–850 | 1.2 | ±0.5 | 40 | 5 |

| LCZN-2×1250 | 0.3–2 | 300–1250 | 1.2 | ±0.5 | 40 | 5 |

| LCZN-2×1600 | 0.3–2 | 300–1600 | 1.2 | ±0.5 | 40 | 5 |

| LCZN-2×1800 | 0.3–2 | 300–1800 | 1.2 | ±0.5 | 40 | 5 |

| LCZN-3×1600 | 0.5–3 | 300–1600 | 1.5 | ±0.5 | 40 | 6 |

| LCZN-3×2000 | 0.5–3 | 300–2000 | 1.5 | ±0.5 | 40 | 6 |

| LCZN-4×1250 | 0.5–4 | 300–1250 | 1.8 | ±0.5 | 40 | 8 |

| LCZN-4×1600 | 0.5–4 | 300–1600 | 1.8 | ±0.5 | 40 | 8 |

| LCZN-4×2000 | 0.5–4 | 300–2000 | 1.8 | ±0.5 | 40 | 10 |

| LCZN-6×1600 | 0.8–6 | 300–1600 | 2.0 | ±0.5 | 40 | 10 |

| LCZN-6×2000 | 0.8–6 | 300–2000 | 2.0 | ±0.5 | 40 | 15 |

| LCZN-8×2000 | 1.0–8 | 300–2000 | 2.5 | ±0.5 | 40 | 15 |

| LCZN-10×2000 | 1.2–10 | 300–2000 | 3.0 | ±0.5 | 40 | 20 |

| LCZN-12×2000 | 2.0–12 | 300–2000 | 3.5 | ±1.0 | 40 | 20 |

| LCZN-16×2000 | 3.0–16 | 300–2000 | 4.0 | ±1.0 | 40 | 25 |

| LCZN-20×2000 | 4.0–20 | 300–2000 | 4.5 | ±1.0 | 40 | 25 |

| LCZN-25×2000 | 5.0–25 | 300–2000 | 5.0 | ±1.0 | 40 | 30 |

| LCZN-30×2000 | 6.0–30 | 300–2000 | 5.0 | ±1.0 | 40 | 30 |

| LCZN-40×2000 | 8.0–40 | 300–2000 | 5.0 | ±1.0 | 40 | 35 |

| LCZN-60×2000 | 10–60 | 300–2000 | 5.0 | ±1.0 | 40 | 35 |

Why do we need to decoiling and leveling, then cutting for blanking?

For sheet coil is low price, but cut-to-length sheet plates are high price

With this blanking line, user prefer sheet coils to cut-to-length steel plate, enabling flexible clipping and much lower costs of purchase because of their large price spread

Share

Contact us !